About Us

1 Day Wheel Repair is a leading wheel repair company dedicated to providing fast, efficient, and high-quality repair services. With a focus on customer satisfaction, we aim to deliver exceptional results while minimizing the inconvenience caused by wheel damage.

We understand that time is of the essence, which is why we prioritize speed without compromising on quality. Our goal is to complete wheel repairs within a single day, allowing you to get back on the road with confidence and minimal disruption to your daily routine. We know how important your wheels are for the safety and performance of your vehicle, and we strive to provide efficient service that exceeds your expectations.

At 1 Day Wheel Repair, we are a trusted and efficient wheel repair service provider serving Houston and surrounding areas. We employ state-of-the-art technology to address any type of wheel damage, from balancing and curb rash repair to straightening, refinishing, and custom painting. Our team of expert technicians has over 22 years of experience in providing top-notch customer service and restoring wheels to their original, like-new condition. Unlike other repair shops, we don't just hammer out dents and call it a day; we take pride in our work and ensure that every wheel is finished with the utmost quality. Our pricing ranges from $90 to $150 depending on the severity of the damage, size, and wheel quality. We specialize in repairing wheels for luxury sports cars and sports bikes, and our technicians are highly skilled in handling even the most delicate of wheels.

Same Day Service Option

Bent Wheel Repair

Bent wheel repair refers to the process of fixing a wheel that has become bent or damaged due to various reasons. A bent wheel can occur from hitting a pothole, curb, or other road hazards, as well as from collisions or accidents. The damage typically results in the wheel being out of shape, causing it to wobble or vibrate while driving.

The repair process involves assessing the extent of the damage and determining the best method to restore the wheel's structural integrity. In some cases, a wheel can be straightened using specialized equipment and techniques. The technician carefully applies controlled pressure to specific areas of the wheel to reshape it back to its original form.

However, it's important to note that not all bent wheels can be repaired. Severe damage, such as cracks or fractures, may render the wheel unsafe and irreparable. In such cases, wheel replacement becomes necessary.

The repair of a bent wheel goes beyond just straightening it. The technician also checks for other potential issues, such as wheel balance and alignment. They ensure that the repaired wheel spins true and smoothly, reducing vibrations and ensuring proper contact with the tire.

To ensure a successful bent wheel repair, it is recommended to seek the assistance of a professional wheel repair specialist or a reputable automotive shop. They have the expertise, experience, and specialized equipment to assess the damage accurately and perform the necessary repairs effectively. By addressing a bent wheel promptly, you can restore the safety, stability, and performance of your vehicle while extending the lifespan of your tires.

1 Day Wheel Repair is a professional wheel repair company dedicated to providing top-quality services for all types of bent wheels. We understand how frustrating it can be to have a bent wheel and the impact it can have on your driving experience. That's why we offer a fast and reliable service that can repair your wheels in just one day, so you can get back on the road as soon as possible.

Our team of experienced technicians uses state-of-the-art equipment and techniques to repair bent wheels, ensuring a high-quality finish that restores your wheels' appearance and performance. We specialize in repairing all types of wheels, including aluminum, alloy, and steel wheels, and can fix a range of issues, from minor bends to major damage.

When a wheel is bent, it can affect the performance and safety of your vehicle. Here are the general steps involved in a bent wheel repair process:

Inspection: A qualified technician will first inspect the wheel to determine the extent of the damage and whether it can be repaired. This may involve checking for visible signs of bending, such as wobbling or uneven tire wear, as well as using specialized equipment to measure the runout of the wheel and assess its overall condition.

Straightening: If the wheel is repairable, the technician will typically use specialized equipment, such as a hydraulic press, to carefully straighten the bent section of the wheel. This process involves applying controlled force to the wheel to gradually bend it back into shape without causing further damage.

Heat Treatment: In some cases, the technician may also use heat treatment to help reshape the wheel. This involves applying heat to the bent section of the wheel to make it more malleable and easier to straighten.

Machining: After straightening the wheel, the technician may use a lathe or other machining equipment to smooth and reshape the repaired area of the wheel. This can help ensure that the wheel is balanced and able to rotate smoothly.

Finishing: Finally, the technician will typically finish the repaired area by sanding, painting, or powder coating it to restore its appearance and protect it against future damage.

It's important to note that not all bent wheels can be repaired. In some cases, the damage may be too severe, or the location of the bend may make it impossible to straighten without compromising the integrity of the wheel. In these cases, the technician may recommend replacing the wheel entirely to ensure the safety and performance of the vehicle.

Overall, the bent wheel repair process requires specialized expertise and equipment to ensure that the repaired wheel is safe, stable, and able to withstand the demands of the road. By having your bent wheel repaired by a qualified professional, you can help ensure that your vehicle is in good condition and ready to handle the challenges of driving.

Cracked Wheel Repair

Cracked wheel repair involves fixing a wheel that has developed cracks or fractures, either due to impact or other factors. A cracked wheel is a serious safety concern, as it compromises the structural integrity of the wheel and can lead to tire failure or even wheel failure while driving.

The repair process for a cracked wheel depends on the severity and location of the crack. In some cases, minor cracks can be repaired through welding or specialized alloy wheel repair techniques. The cracks are carefully cleaned, and the damaged area is prepared for welding. Skilled technicians use precise welding techniques to fill the crack and restore the wheel's strength.

However, it's important to note that not all cracked wheels can be repaired. If the cracks are extensive, deep, or in critical areas of the wheel, the structural integrity may be compromised beyond repair. In such cases, wheel replacement is necessary to ensure safety.

Repairing a cracked wheel is a specialized process that requires the expertise of a professional wheel repair specialist or a reputable automotive shop. These experts have the knowledge and equipment to properly assess the extent of the damage and determine the most suitable repair method. They will ensure that the repair is performed to industry standards and that the wheel is safe for use.

If you suspect a cracked wheel, it's crucial to address the issue promptly. Ignoring or delaying repairs can lead to further damage and potential hazards while driving. Regular inspections and maintenance of your wheels can help identify cracks early on and allow for timely repairs.

Remember, the safety of your vehicle and your own well-being are paramount. If you notice any signs of a cracked wheel, consult a professional to assess the damage and determine the best course of action for repair or replacement.

Inspection: A qualified technician inspects the wheel to evaluate the extent of the damage and determine if it can be repaired. This involves examining the location, size, and shape of the crack, as well as checking for any other signs of damage or wear.

Welding: If the crack is repairable, the technician will use specialized welding equipment and techniques to weld the affected area. This process involves applying heat and pressure to fuse the metal back together.

Machining: After welding, the technician may use a lathe or other machining equipment to smooth and reshape the repaired area of the wheel. This helps ensure that the wheel is balanced and able to rotate smoothly.

Finishing: The repaired area is then finished by sanding, painting, or powder coating it to restore its appearance and protect it against future damage.

It's important to note that not all cracked wheels can be repaired. In some cases, the damage may be too severe, or the location of the crack may compromise the integrity of the wheel. In such situations, the technician may recommend replacing the damaged wheel entirely to ensure the safety and performance of the vehicle.

Overall, the cracked wheel repair process requires specialized expertise and equipment to ensure that the repaired wheel is safe, stable, and able to withstand the demands of the road. By entrusting your cracked wheel to a qualified professional, you can help ensure that your vehicle is in optimal condition and ready to handle the challenges of driving.

Curb Rash Repair

Cleaning: The damaged area of the wheel is thoroughly cleaned and degreased to remove any dirt, debris, or other contaminants.

Sanding: The damaged area is sanded down to remove any sharp edges, smooth out rough patches, and prepare the surface for repair.

Filling: A specialized filler is applied to the damaged area to fill in any gaps or deep scratches. This filler is typically made from a material that is both durable and able to withstand the heat and stress of driving.

Sanding Again: Once the filler has dried, the technician will sand it down to create a smooth, even surface. This helps ensure that the repaired area blends seamlessly with the rest of the wheel.

Painting: The repaired area is then painted to match the color and finish of the rest of the wheel. This can involve using specialized equipment to apply multiple layers of paint and clear coat to achieve a smooth, glossy finish.

Finishing: Finally, the repaired area is finished by polishing, buffing, or powder coating it to protect it against future damage and ensure that it looks as good as new.

Overall, the process of repairing curb rash on a wheel requires specialized knowledge, skills, and equipment to ensure that the repair is effective, long-lasting, and aesthetically pleasing. By having your curb-rashed wheel repaired by a qualified professional, you can help ensure that your vehicle looks its best and is ready to handle the demands of the road.

Excellence through Passion

Caliper painting

Caliper painting is a cosmetic upgrade that involves painting the brake calipers of a vehicle to give it a sportier, more customized look. Here are the general steps involved in the caliper painting process:

Preparation: The technician will first prepare the brake calipers by cleaning them with a degreaser to remove any dirt, grease, or other contaminants. The calipers are then sanded or wire-brushed to create a smooth, clean surface for the paint to adhere to.

Masking: The surrounding areas of the calipers are masked off with tape or paper to protect them from overspray.

Painting: The technician will then apply a high-temperature paint specifically designed for use on brake calipers. This paint is typically available in a range of colors and finishes, allowing for a customized look.

Drying: After the paint has been applied, it is left to dry for a specified period of time to ensure that it fully cures.

Clear Coating: To protect the paint and create a glossy finish, the technician may apply a clear coat over the painted surface.

Finishing: Once the paint and clear coat have dried, the masking tape and paper are removed, and any remaining residue is cleaned off.

Overall, caliper painting is a relatively simple process that can be completed in a few hours. However, it requires specialized knowledge and equipment to ensure that the paint adheres properly and does not peel or chip over time. By having your brake calipers painted by a qualified professional, you can help ensure that your vehicle looks its best and is ready to make a statement on the road.

Blackout Packages

A blackout package is a customization option that involves "blacking out" various parts of a vehicle, such as the wheels, grille, trim, emblems, and other exterior components. The specific steps involved in a blackout package will vary depending on the vehicle and the parts being customized, but here are some general steps that may be involved:

Overall, a blackout package can be a great way to give your vehicle a unique and customized look, but it requires specialized knowledge and equipment to ensure that the finish is durable, long-lasting, and looks great. By having your blackout package installed by a qualified professional, you can help ensure that your vehicle stands out from the crowd and looks its best on the road.

Assess the vehicle to determine which chrome parts will be removed or covered up. This may include the grille, window trim, door handles, side mirrors, and other chrome accents on the exterior.

Gather the necessary tools and materials for the job, such as trim removal tools, sandpaper, primer, paint, and clear coat.

Clean the surfaces to be painted thoroughly to remove any dirt, debris, or wax that may interfere with the adhesion of the paint.

Use a trim removal tool to carefully remove any chrome parts that will be replaced or painted over. Take care not to damage any surrounding surfaces or components.

Sand the surfaces to be painted lightly to create a rough surface for the primer to adhere to. Wipe away any dust or debris.

Apply a primer to the sanded surfaces to provide a base for the paint to adhere to. Allow the primer to dry according to the manufacturer's instructions.

Apply several thin coats of paint to the primed surfaces, allowing each coat to dry completely before applying the next. Use a high-quality automotive paint that matches the color of the vehicle.

Apply a clear coat over the painted surfaces to protect the paint and create a glossy finish. Allow the clear coat to dry completely before handling or re-installing any parts.

Re-install any parts that were removed, either by replacing them with new non-chrome parts or by re-installing the original parts that were painted over.

Inspect the finished product and make any necessary touch-ups or adjustments to ensure a high-quality, professional-looking result.

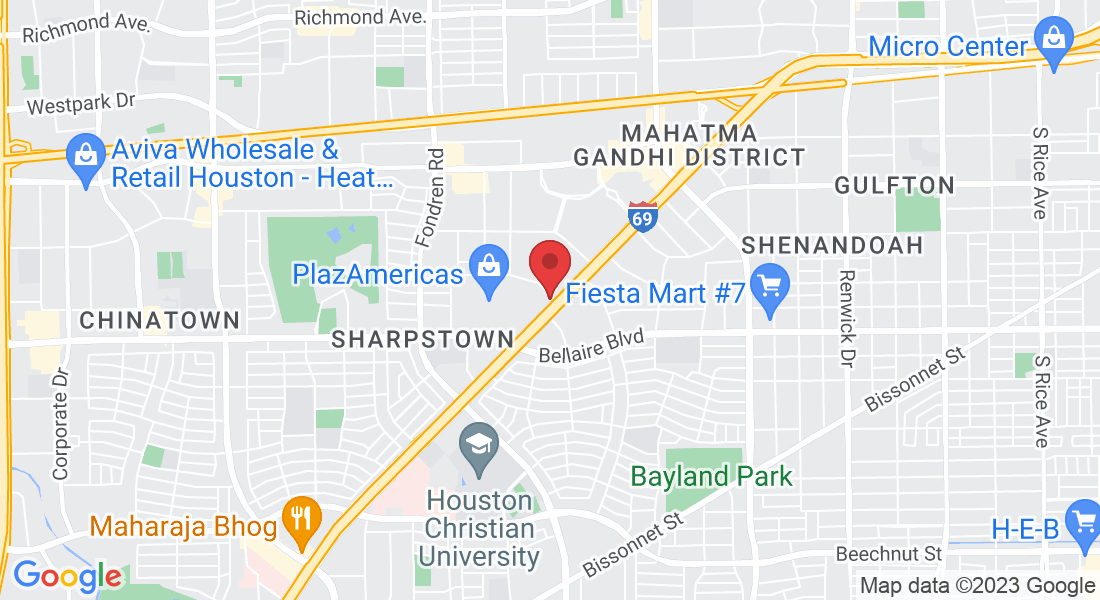

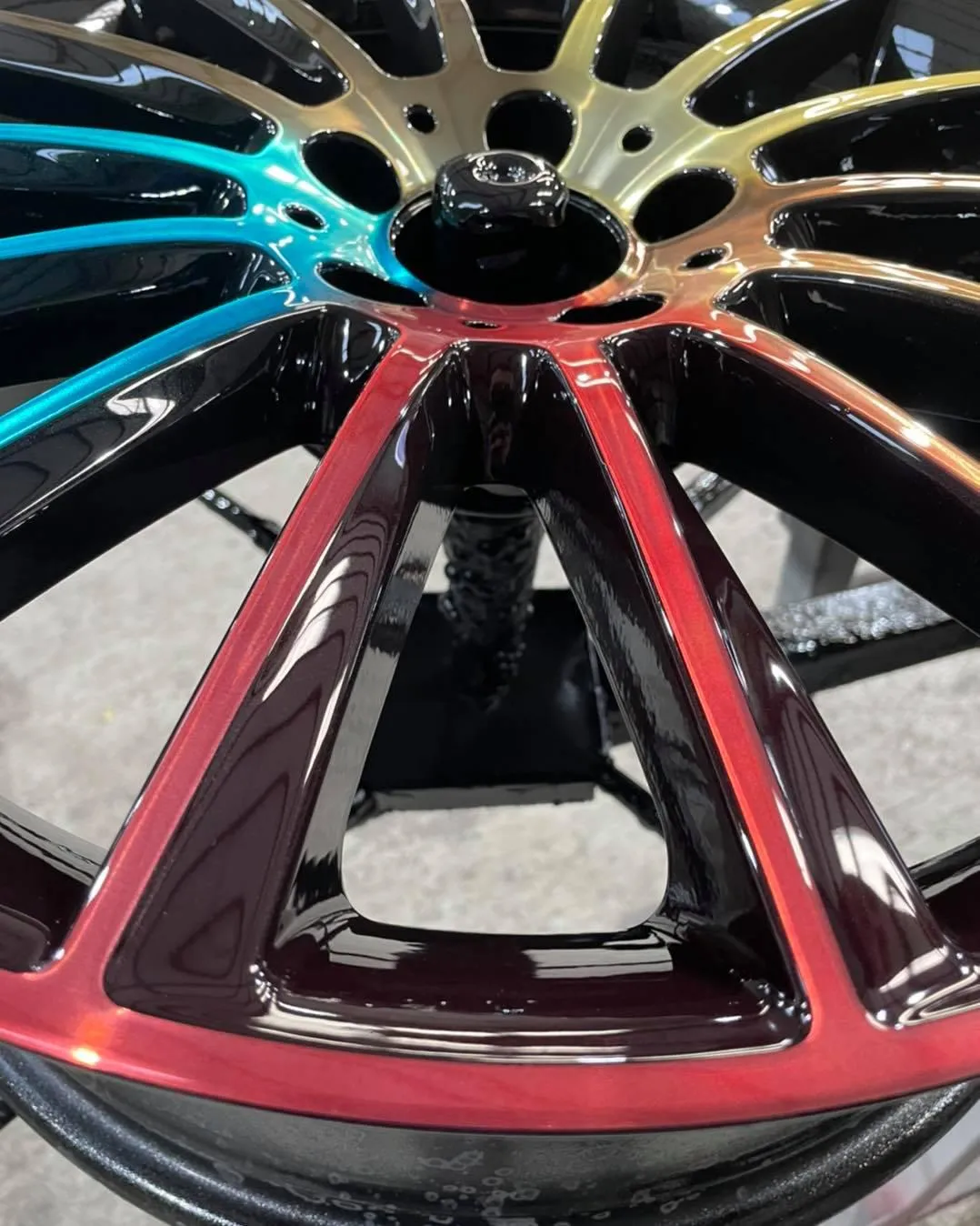

Custom Painting

Custom painting your wheels is a great way to add a personal touch to your vehicle and make it stand out on the road. Here are the general steps involved in the custom painting process for wheels:

Preparation: The wheels are thoroughly cleaned and degreased to remove any dirt, oil, or other contaminants. They are then sanded or bead-blasted to create a rough surface that allows the paint to adhere properly.

Masking: The areas of the wheel that should not be painted, such as the lug nut holes and valve stem, are masked off to protect them from the paint.

Primer: A primer is applied to the wheel to help the paint adhere and create a smooth, even surface for the topcoat.

Painting: The wheels are then painted with a specialized paint that is designed for use on metal surfaces. This can involve using a spray gun or other specialized equipment to apply multiple layers of paint to achieve the desired level of coverage and finish.

Drying and Curing: After the paint has been applied, the wheels are left to dry and cure for a specified period of time to ensure that the finish is fully set and won't chip, peel, or wear away over time.

Finishing: Once the paint has fully cured and cooled, the masking tape and paper are removed, and any remaining residue is cleaned off. The wheels may be finished with a clear coat or polishing compound to give them a glossy shine.

Overall, the custom painting process for wheels requires specialized knowledge, skills, and equipment to ensure that the paint adheres properly and creates a high-quality finish. By having your wheels custom painted by a qualified professional, you can create a unique and personalized look for your vehicle that reflects your personal style and enhances its overall appearance.

Powder Coating

If you're looking to give your car a sleek new look, powder coating your wheels is a fantastic option. Powder coating is a durable and long-lasting finishing process that involves electrostatically applying a dry powder to the surface of your wheels, which is then cured under heat to create a smooth and even finish.

With powder coating, you can choose from a wide range of colors and finishes to customize the look of your wheels to match your personal style. Not only does this provide a great aesthetic upgrade, but it also helps protect your wheels from the elements and general wear and tear, making them easier to clean and maintain.

At our powder coating shop, we use only high-quality materials and techniques to ensure that your wheels receive the best possible finish. Our experienced team will work with you to understand your vision and provide recommendations to help you achieve the desired result.

Preparation: Before powder coating, the wheels need to be thoroughly cleaned and prepared. This involves removing any existing coatings, rust, or debris from the surface of the wheels. The wheels are then washed and dried to ensure a clean surface for the powder coating.

Masking: If there are areas of the wheel that should not be coated, such as the tire bead or hub, these areas need to be masked off to protect them from the powder coating.

Application: The powder coating is applied to the surface of the wheels using an electrostatic spray gun. The powder particles are charged and attract to the grounded wheel surface, creating an even and consistent coating.

Curing: Once the powder coating is applied, the wheels are placed in a curing oven where they are heated to a specific temperature for a certain amount of time. This allows the powder to melt and fuse together, creating a durable and smooth finish.

Cooling: After the curing process, the wheels are removed from the oven and allowed to cool down to room temperature. This allows the powder coating to harden and set properly.

Inspection: Once the wheels are cool, they are inspected for any imperfections or issues with the coating. Any areas that need touch-ups or corrections can be addressed at this stage.

Following these stages carefully ensures a high-quality and long-lasting powder coating finish for your wheels.